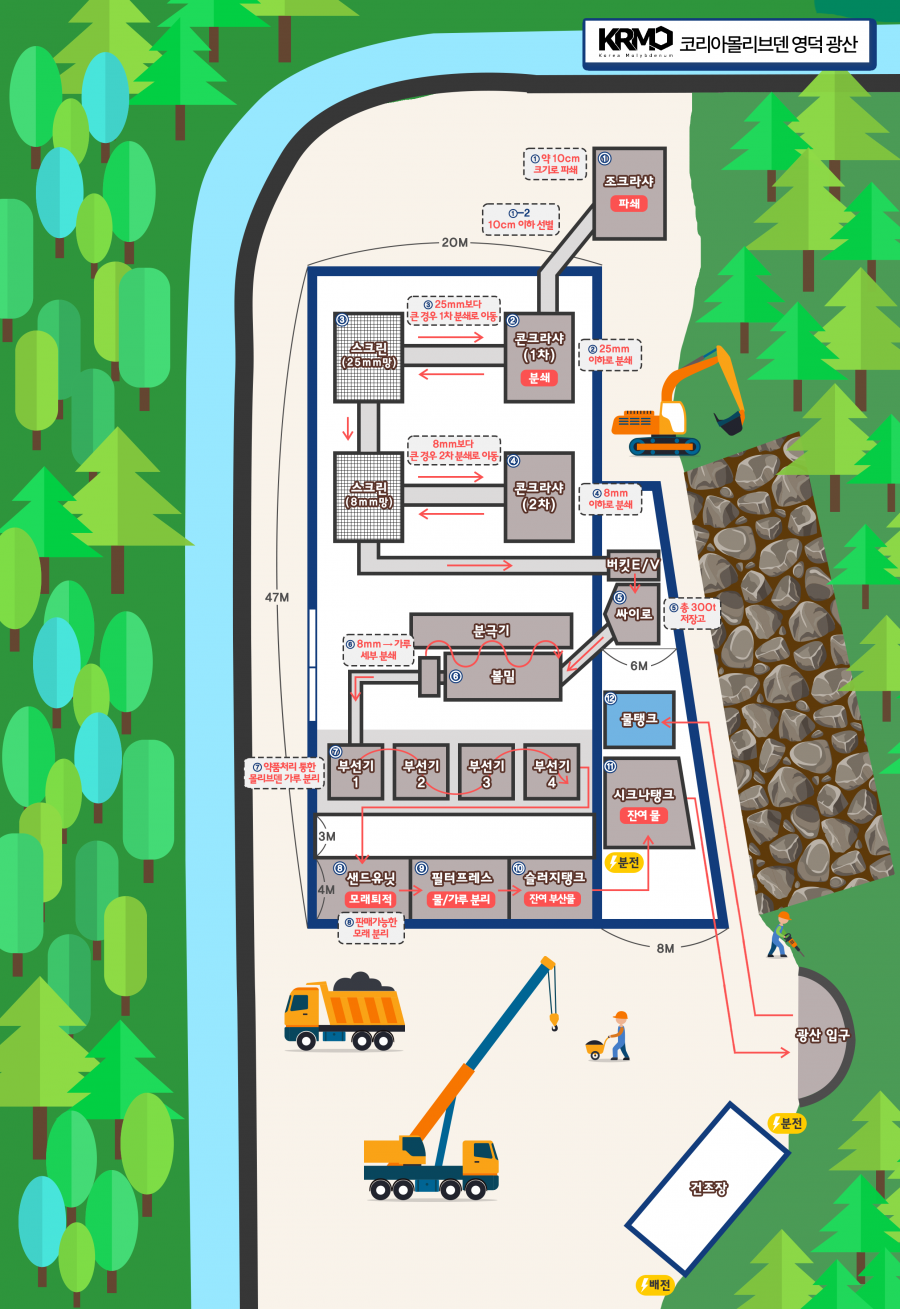

Schematic illustration and processing sequence of Yeongdeok mine minin…

페이지 정보

본문

This is the order of the molybdenum light treatment work for the Sunlight Plant scheduled to be built in Yeongdeok Mine.

⠀

01. Load ore mined inside the mine in a 15-ton truck and transport it to Jokrasha and crush it to a size of about 10cm.

The crushed ore is integrated into the hopper and moved to the conveyor belt, from the conveyor belt to the primary concrete.

⠀

02. Crush the ore into a size of 25mm or less in the 1st concrete bar and move it to the 2nd concrete bar.

If the crushed ore is larger than the standard, select the ore from the primary screen. After moving to the first concrete, re-crushing work is carried out.

⠀

03. Crush the ore to a size of 8mm or less in the second concrete and move it to the bucket elevator through the conveyor belt.

If the crushed ore is larger than the specification, select the ore from the secondary screen, move it to the secondary concrete, and then proceed with the re-crushing.

⠀

04. Load up to 300 tons of ore less than 8 mm into the silo through the bucket elevator.

⠀

05. Move the loaded ore through the conveyor belt to the primary ball mill.

In the ball mill, the tungsten alloy beads rotate and collide, crushing the ore to powder sizes of 0.6 mm or less.

If the pulverized powder is larger than the specification, select the powder from the polarizer, move it to the secondary ball mill, and then proceed with re- pulverization.

The pulverized powder moves to the flotation machine for classification.

⠀

06. In the floating machine, treat the crushed powder with chemicals and classify it into molybdenum powder and other ore powder.

⠀

07. Other ore powders are moved to sand units and classified into available and non-soldable sludge through specific gravity screening.

⠀

08. After squeezing out the sludge water from the filter press and separating it,

Sludge accumulates in the sludge tank, and water accumulates only clear reusable water in the chic or tank.

⠀

09. Move the accumulated clear water to the water tank and reuse it for floating machine work

The insufficient water is circulated using the replenishment water installed inside the mine.

⠀

In addition, the current Yeongdeok mine has a hand-packing area between Jokrasha and Konkrasha for rapid classification of the ore

We are planning to install the third vertical ball mill to go through one more process after the second ball mill work.